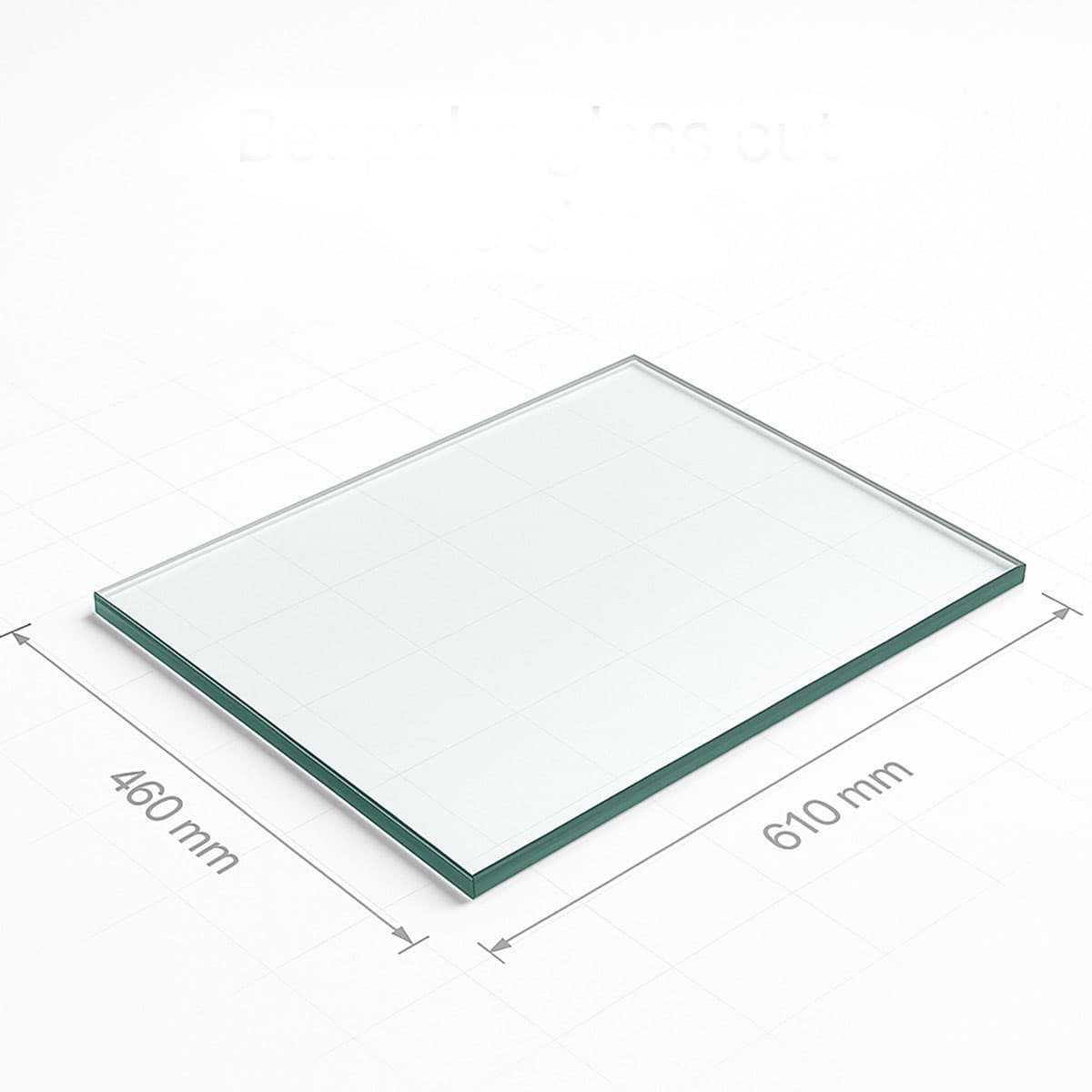

Bespoke cut to size glass toughened glass

Precision-cut toughened glass made to your exact measurements, offering strength, safety, and a perfect fit for any project.

Product Gallery

Bespoke glass cut to size

Bespoke cut to size glass toughened glass

Precision-cut toughened glass made to your exact measurements, offering strength, safety, and a perfect fit for any project.

Product Information

Complete specifications, applications, and technical details

Product Overview

Our bespoke cut-to-size toughened glass is manufactured to meet BSEN 12150 safety standards, ensuring strength, durability, and peace of mind. Each panel is precisely cut to your exact measurements, providing a perfect fit for your project. Toughened through a controlled heating process, this glass is significantly stronger than standard glass and is designed to resist impact and thermal stress. Ideal for both residential and commercial use, it offers versatility for a wide range of applications, including shelves, partitions, balustrades, splashbacks, tabletops, and more. Whether you're looking for a sleek, modern finish or a robust, practical solution, our toughened glass delivers excellent performance, safety, and style.

Technical Specifications

- Material

- Toughened Safety Glass

- Manufacturing Standard

- BS EN 12150-1

- Maximum Size

- 3000mm × 2000mm

- Minimum Size

- 250mm × 100mm

- Tolerances

- +/-3mm accuracy on target dimension

- Available Thicknesses

- 6mm, 8mm, 10mm, 12mm, 15mm, 19mm

- Heat Resistance

- Up to 250°C

- Safety Rating

- 5× stronger than standard glass

Edge Finishes

- Polished edges - smooth, clear finish for visible edges

- Arrised edges - slightly rounded corners for safety

- Beveled edges - angled cut for decorative effect

- Straight cut - standard factory edge (for hidden edges only)

Polished edges are recommended for any glass edge that will be visible or touched regularly.

Toughening Stamp Details

A visible toughening stamp will be placed on the edge of all polished glass to certify compliance with BS EN 12150-1 safety standards.

Stamps on arrised edge glass will have a small circular toughening stamp on the face of the glass in a bottom corner.

If specific edges or stamp locations are required, please advise in the notes section or contact us before ordering.

Lead Time & Delivery

- Standard Lead Time

- 7-10 working days (may vary with quality control)

- Express Service

- Available - please enquire

- Delivery

- UK mainland delivery available

- Packaging

- Secure crating with protective materials

Lead times are estimates and may vary based on order complexity and current production schedule. Express service may be available for urgent orders - please contact us to discuss.

Common Applications

Table Tops

Custom-cut glass table tops for dining tables, coffee tables, and desk surfaces. Available in various thicknesses to suit your furniture and usage requirements.

Shelves

Glass shelving for bookcases, display cabinets, bathrooms, and general storage. Cut to your exact measurements with polished edges for a professional finish.

Screens & Partitions

Glass panels for room dividers, shower screens, and privacy partitions. Clear or frosted options available for different levels of privacy.

DIY Projects

Custom glass cutting for home improvement projects, furniture making, and craft applications. Perfect for bespoke solutions.

Key Features

- Custom cut to your exact measurements

- Toughened safety glass (4-5× stronger than regular glass)

- Various edge finishes available

- Optional corner treatment for safety

- Heat-resistant up to 250°C

- Easy clean coating available

- Precision CNC cutting technology

- BS EN 12150-1 certified

Installation Guidelines

- 1Ensure the supporting surface is level, clean, and free from debris. Check that the area can support the weight of the glass.

- 2Use appropriate fixings for your application - adhesive pads, brackets, or clips depending on the installation type.

- 3For table tops, use clear silicone pads or adhesive bumpers between the glass and surface to prevent slipping and allow air circulation.

- 4For shelves, use dedicated glass shelf brackets with rubber inserts to grip the glass securely without causing stress points.

- 5Always handle toughened glass with care. While stronger than standard glass, it cannot be cut, drilled, or modified after toughening.

- 6When installing, have at least two people to handle larger panels safely. Use suction cups for easier handling of smooth surfaces.

Care & Maintenance

- Clean with standard glass cleaner or warm soapy water

- Use a soft, lint-free cloth or squeegee

- Avoid abrasive cleaners or rough materials

- Dry thoroughly to prevent water spots

- Regular cleaning maintains clarity and appearance

For easy-clean coated glass, use only recommended cleaning products to maintain the protective coating.

Safety Information

Toughened glass is designed to be safer than standard glass. If broken, it shatters into small, relatively harmless pieces rather than large, sharp shards.

- BS EN 12150-1 certified for safety compliance

- 5× stronger than standard annealed glass

- Resistant to thermal stress and impact

- Cannot be cut or drilled after toughening

- Small chips at edges should be monitored

- Keep edges protected during installation

While toughened glass is extremely strong, it can still break under extreme impact or if edges are damaged. Always handle with care and inspect edges regularly.

Ordering Process

- 1Enter your exact measurements in millimeters (width × height)

- 2Select your glass thickness - consider the application and size

- 3Choose your preferred edge finish (polished recommended for visible edges)

- 4Add optional features like corner treatments, drilled holes, or coatings

- 5Calculate your price to see a detailed breakdown

- 6Add to cart or request a quote - both options preserve your configuration

- 7Proceed to checkout or wait for our quote response

Measurement Tips

- Always measure in millimeters for accuracy

- Measure twice to confirm dimensions

- Account for +/-3mm manufacturing tolerance

- For table tops, measure the surface you want to cover

- For shelves, measure the alcove or bracket spacing

- Consider if you need corner rounding for safety

- Note any cutouts or holes required during configuration

If you're unsure about measurements or have a complex requirement, please contact us before ordering. We're happy to provide guidance to ensure you get exactly what you need.

What Happens Next

- 1Order confirmation sent immediately via email

- 2Technical review of your specifications (1 working day)

- 3Any questions or clarifications communicated promptly

- 4Production begins once specifications are confirmed

- 5Quality control inspection before dispatch

- 6Secure packaging and delivery arranged

- 7Tracking information provided when dispatched

Select Dimensions, quantity, thickness and glass types

Enter Your Dimensions

Specify the exact size of your glass panel. All measurements are in millimeters.

Min: 100mm, Max: 2500mm

Min: 100mm, Max: 2500mm

Glass Thickness

Glass Type

Select edge finish and corner finishes

Edge Finish

Corner Finish (Optional)

Additional addons

Any extra optional add ons

Additional Treatments (Optional)

Drilled Holes (Optional)

No drilled holes configured yet. Add holes for mounting fixtures.

Hole diameter size must equal to or greater than the thickness of the glass.

Notes

Additional Notes (Optional)

Finish

Scroll up to make any changes and or add to cart

Ready to Calculate?

All options configured. Click below to calculate your price.

Please Fix These Issues:

Width required, Height required

Order Summary

Width required, Height required

Width required, Height required

Frequently Asked Questions

Common questions about our cut-to-size glass service

What is toughened glass and why should I use it?

Toughened (tempered) glass is safety glass that has been heat-treated to be 4-5 times stronger than regular glass. If it breaks, it shatters into small, relatively harmless pieces rather than large, dangerous shards. We recommend toughened glass for any application where safety is a concern, including table tops, shelves, partitions, and anywhere the glass might be subject to impact or thermal stress.

Can I cut or drill toughened glass after it arrives?

No, toughened glass cannot be cut, drilled, or modified after the toughening process. Any cutting, drilling, or shaping must be done before toughening. This is why it's crucial to provide exact measurements and specify all holes, cutouts, and corner treatments when ordering. If you need modifications, please contact us before placing your order.

What's the difference between polished and arrised edges?

Polished edges are ground and polished to a smooth, clear finish. They're ideal for any glass edge that will be visible or touched regularly, such as table tops and shelves. Arrised edges have the sharp corners slightly rounded for safety but aren't fully polished. They're suitable for glass that's framed or where edges are less visible, and are more cost-effective than polished edges.

How accurate will my measurements be?

Our glass is cut with CNC precision to ±3mm tolerance on all dimensions. This is industry standard for custom-cut glass and accounts for the manufacturing process. If you need tighter tolerances for a specific application, please contact us to discuss your requirements before ordering.

What thicknesses do you recommend for different applications?

6mm: Small shelves, picture frames, cabinet doors (up to 600mm span). 8mm: Medium shelves, worktops, small table tops (up to 900mm span). 10mm: Large shelves, dining tables, desks (up to 1200mm span). 12mm+: Large table tops, heavy-duty applications, architectural features. These are general guidelines - contact us if you're unsure which thickness suits your needs.

How long does delivery take?

Standard lead time is 7-10 working days from order confirmation. This includes manufacturing, quality control, and secure packaging. Lead times may vary based on order complexity and current production schedule. Express service may be available for urgent orders - please contact us to discuss.

Can I return or exchange custom-cut glass?

Because each piece is custom-manufactured to your exact specifications, we cannot accept returns or exchanges unless the glass is faulty or doesn't match your order specifications. We recommend double-checking all measurements before ordering. If you're unsure, please contact us for guidance.

Do you provide installation services?

We primarily supply cut-to-size glass for DIY installation or for your contractor to fit. However, we can recommend experienced installers in your area. We provide detailed guidance on safe handling and installation, including recommended fixings and brackets for different applications.

What's the maximum size glass you can produce?

Our maximum glass size is 3000mm × 2000mm. The minimum size is 250mm × 100mm. For very large panels, we can discuss your requirements and may be able to offer alternative solutions or multi-panel designs.

Where does the toughening stamp appear on the glass?

On polished edge glass, a visible toughening stamp appears on the edge. On arrised edge glass, a small circular stamp appears on the face in a bottom corner. If you need specific stamp locations, please note this in your order or contact us before ordering.